Roof Systems

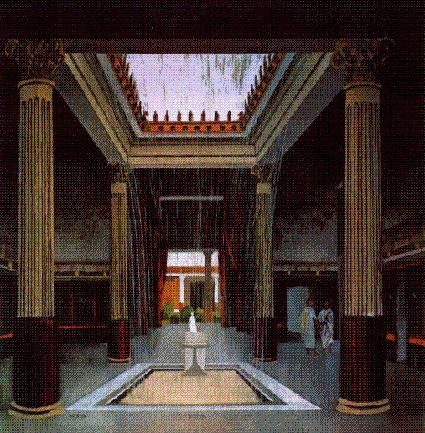

Roof collection of water and storage in atrium pools and cisterns was a well developed technology in ancient Rome. From archaeology in Pompeii (79 AD.) we can accurately reconstruct the system of rainwater catchment as shown in the image below.

Atrium in ancient Rome (Jashemski, 1979)

There are six components to a rooftop collection system, depending on the degree of quality required (Winterbottom, 2000). These six components are catchment, roof-wash system, conveyance to storage, filtration, storage or cisterns, and distribution (Winterbottom, 2000)

Catchment

Catchment areas can be anything relatively flat with slight slope of an impervious surface. The most common catchment area is a roof. There are a few things to take into consideration when creating a roof with the intent to harvest water. Roofing material is perhaps the biggest concern in roof catchment areas. Some roofing materials (such as wood shakes and clay tiles) can create an environment that harbors algae and bacteria, which can contaminate the water. This is not a large concern if the water is not to be consumed. Other roofing materials, like asphaltic roofing, have a tendency to collect dust and particle pollutants which may also contaminate the water (Winterbottom, 2000). These roofing materials also tend to be porous and will absorb more water then metal surfaces. Another factor for consider is the "material's leachate capability." This is a problem when metal roofing materials are coated with zinc, wood materials are treated with preservatives, and asphaltic materials release petrochemicals (Winterbottom, 2000). The best materials for roof catchment areas are stainless steel or galvanized steel with baked-on finish (Winterbottom, 2000). Catchment areas should also be kept away from trees and branches as they provide leaf particles that will clog the system and they provide an access to the roof for animals and birds, both of which have the capability to do contamination damage.

Roof-wash system

Conveyance

From the catchment area, the rain water is channeled through gutter, pipes, and downspouts to the storage basin, or cistern. The rules for material choice of pipes should follow closely to those of the roof materials. Avoid metals that will contaminate with zinc or lead. The conveyance system size should allow for 1.25 inches of water in a ten minute period (Winterbottom, 2000).

Filtration

Filtration begins with the aforementioned roof wash system, but can become more complex depending on the desired purity of the water. Leaf screens should be placed on the inlets and outlets to catch the large particles that may get into the storage unit and provide a source of food for harmful bacteria. Another way to filter the water is to use a gravel filter. This is a device filled with pea gravel and lava rock that the water falls into. As the water level rises, the large particles are left at the bottom and the clear water runs off into the storage tank. Other methods of filtration are micro-filters, which use sand, charcoal and gravel to filter the water into a potable state, UV sterilization and ozonation. The later two filtration system are more costly, but perhaps a little more reliable.

Storage

Ancient s tone storage

The storage unit or cistern is perhaps the biggest element in a rainwater harvesting system for more then one reason. It is no doubt the largest elements when comparing sizes, but it is often the most expensive element. It also happens to be the most limiting, as its size will determine how much water can be stored for future use. Storage units come in all shapes, sizes and materials. The most common shape in cylindrical due to the strength to weight ratio (Winterbottom, 2000).

The elements of storage units is relatively universal, no matter the shape or size. There is, of course, an inlet from which the water enters the storage unit. Typically an overflow outlet is placed in the unit at the desired maximum water level to prevent overflow and water waste. A drain is often placed at the bottom of the storage unit so that the unit can be drained for maintenance, repair, or cleaning.

Common materials for storage units are galvanized steel, concrete, ferrocement, mortared stone, fiberglass, polyethylene tanks, wood stave tanks, and polyethylene liners in excavated holes.

- Galvanized steel is the most common material used for storage units. When concrete is used, it is often submerged into the ground at least partially.

- Ferrocement is a lower cost concrete unit.

- Mortared stone storage units are perhaps the oldest of the storage units. If designed properly, they can dominate the design and be quite attractive.

- Fiberglass is probably the least expensive, but possibly the least attractive as well.

- Polyethylene tanks are light weight and easy to transport but expensive.

- Wood stave tanks should be constructed carefully and without preservatives.

- Polyethylene liners are the lowest cost, but don't last as long as some of the other options (Winterbottom, 2000).

A major drawback to water harvesting is the site of the storage tanks. Most people do not appreciate large, unwieldy tanks in their back yards or around the property. There are ways to disguise these monstrosities. The tanks, depending on the material they are made of, can be buried or partially buried. Sometimes they can be placed under decks or hidden by vegetation. Wood cisterns can be purchased that look more like a garden shed then a huge water tank. Another approach to "hiding" the cisterns is to embrace them and design around them. Make them the focal element in the design. This was successfully done by the students and University of Washington when they designed a water harvesting system for Garden of Eat'in. The cistern used in this project is made of galvanized steel with the dimensions of 13 feet high and a 6 foot diameter (Winterbottom, 2000). This tank has the capacity to hold 4,500 gallons of water (Winterbottom, 2000). The overflow outlet was handled as an opportunity to create a unique sculpture that would drain the water to a storm-water system. "The tower has become an unexpected design amenity, serving as an icon for both the park and the west campus.

Storage units come in many sizes. Depending on the material they can be made to order in any size that fits the designers plan. For simple irrigation purposes, small clay pots can be used. These can also add unique charm to a garden. For industrial purposes, many large storage units can be combined. In this case, it is better to incorporate the tanks into the design, or hide them altogether. For sizing see roof catchment calculations.

Distribution

Distribution can rely on gravity, if the storage tank is above the site requiring the water supply. Pumps and pressure tanks may be used otherwise.